Avoid mistakes when retrofitting to LED: a practical checklist

Published December 16th, 2025

The term retrofit refers to the modernisation of existing systems or equipment. In lighting, retrofit means integrating modern LED technology into existing luminaires and fixtures. Replacing fluorescent tubes with LED tubes is the most economical and sustainable solution – provided that typical mistakes are avoided.

130.000 h

service life

IEC EN 62776

1:1 replacement T5/T8

-40°C bis +70°C

industrial-grade

up to 80%

energy saving

Mistake 1: Using incompatible LED tubes

To maintain CE conformity, fire safety, and electrical inspection compliance, the use of a compatible LED light source is essential. The LED tube must meet the requirements for LED retrofit according to IEC EN 62776 and be compatible with the existing socket.

Important points:

- T5 LED tube only for G5 sockets

- T8 LED tube only for G13 sockets

LED retrofit tubes are therefore available for all common sockets (G5/G13) and standard lengths. In case of uncertainty, a qualified electrician or the manufacturer should be consulted.

Mistake 2: Incorrect wiring during installation

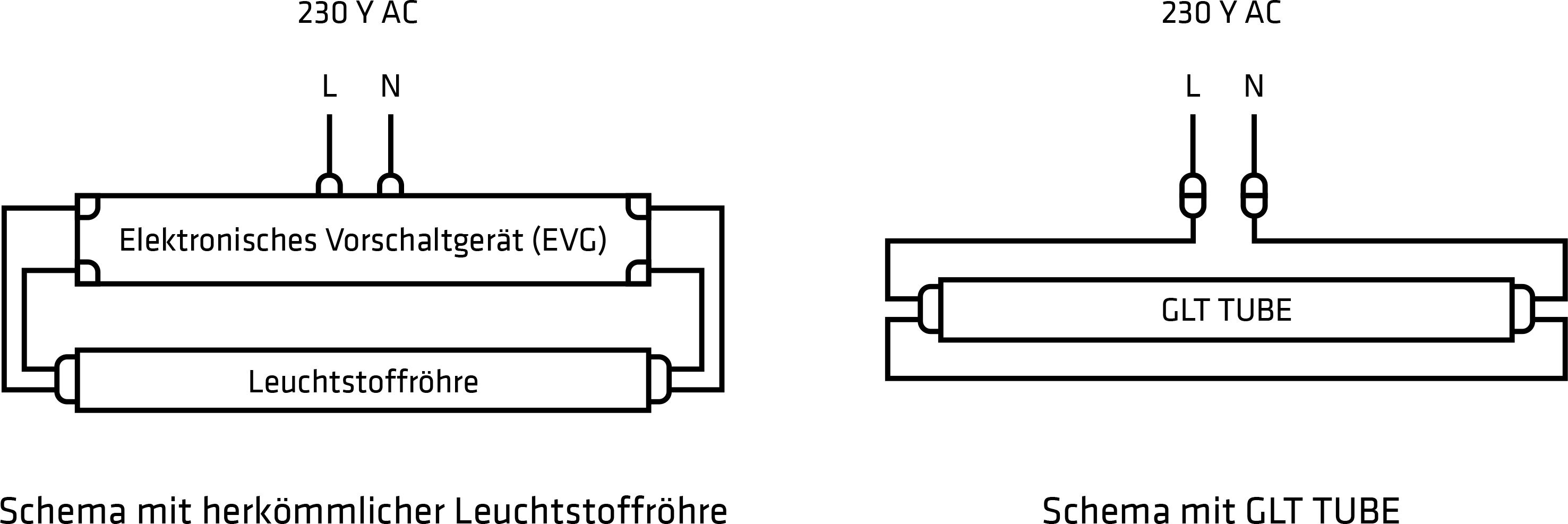

High-quality LED tubes feature an integrated driver and operate directly on 230 V. External ballasts must be decommissioned. Incorrect rewiring poses a safety risk and reduces both efficiency and functionality of the lighting system.

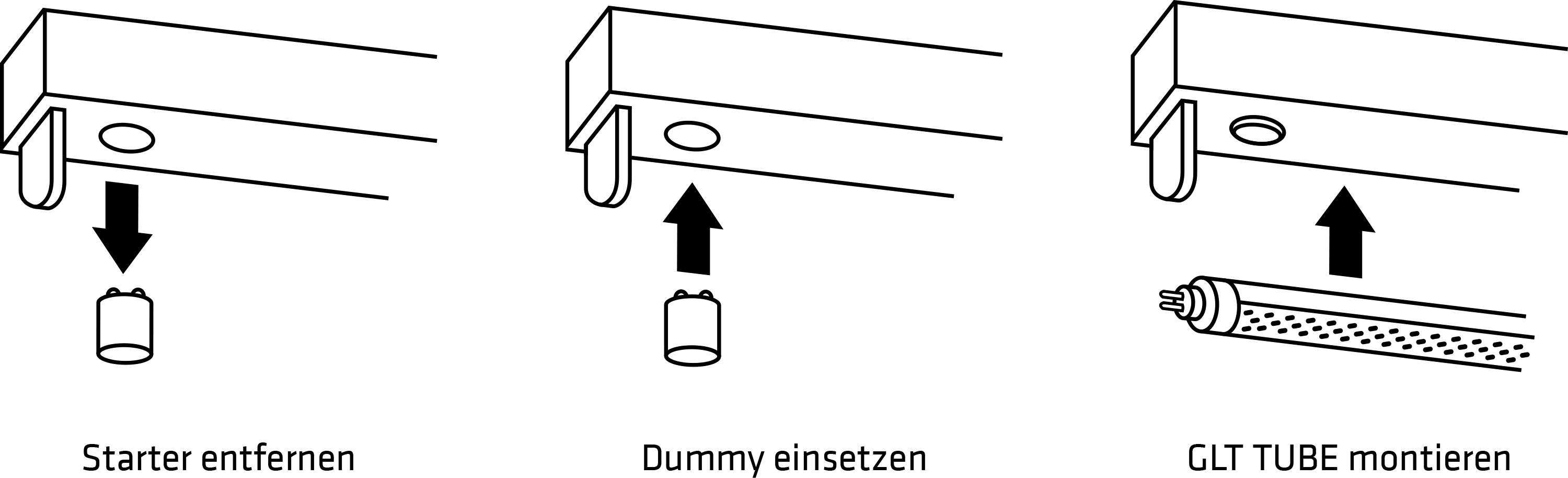

- CCG/VVG: Remove the starter and replace it with a dummy → install LED tube.

- ECG: One-time rewiring by a qualified electrician required, afterwards simple lamp replacement.

Mistake 3: Incorrect assessment of service life

Service life is the most important factor for both quality and economic efficiency. The longer the lifetime, the lower the maintenance and replacement costs.

Key factors:

- L70 rating ≥ 100,000 h (GLT LED TUBE: 130,000 h).

- Documented failure rate (GLT LED TUBE: < 1% over 50,000 h).

- Operating temperature range –20 °C to +60 °C in accordance with EN 62776 (GLT LED TUBE: -40°C up to +70°C).

Note: Very low-cost LED tubes often reach only around 30,000 hours service-life at an ambient temperature of -20°C up to +45°C.

Mistake 4: Misjudging energy efficiency and quality

In addition to lifetime, energy efficiency is the greatest economic lever.

Key factors:

- Integrated high-performance driver: external ballasts cause additional power losses

- High-quality LEDs

- High luminous efficacy (lm/W) (GLT LED TUBE up to 210 lm/W)

- Aluminium carrier profile instead of plastic

- Impact-resistant polycarbonate cover (IK10)

- IFS compliance, if required for food processing areas

Mistake 5: Insufficient light quality

Light quality directly affects productivity, safety, and well-being. Typical mistakes include incorrect colour temperature or insufficient colour rendering.

Colour temperature (Kelvin):

- 6,500 K → cold, not suitable for human working environments

- 4,000–5,000 K → standard for professional environments

- 3,000 K → warm, residential areas and rest zones

Colour rendering (CRI / Ra):

- Ra 80 → standard

- Ra ≥ 90 → high colour fidelity for demanding applications

Important: comply with workplace lighting standards (DIN EN 12464-1).

Mistake 6: Incorrect ROI calculation

A profitability calculation shows when the retrofit pays off. It considers acquisition costs, energy savings, service life, and maintenance costs.

Whether purchase or rental – use the GLT calculator to calculate your savings.

GLT calculator - calculate savingsGLT calculator - calculate savings

Mistake 7: Ignoring ecology and environmental impact

Choose quality Made in Europe and verified environmental data. Around 80% of LED tubes currently come from Asia and are neither repairable nor recyclable – they are disposed of as electronic waste at end of life.

We counter this trend with the GLT LED TUBE, designed according to the principles of Circular Lighting:

- EPD according to ISO 14025 and EN 15804 (cradle to grave)

- ESG-compliant CO₂ footprint

- Repairability & GLT multi-use system

- Recycling rate approx. 90%

Mistake 8: Forgetting standards compliance

Check compliance with the following standards (review the data sheet):

- IEC EN 62776 – LED retrofit G5/G13

- EU Ecodesign Regulation 2024/1781 (ESPR) – product quality, durability, repairability, recyclability

- RoHS Directive – restriction of hazardous substances

- ENEC – electrical safety & EMC

Since August 2023, T5/T8 fluorescent tubes are banned. Continued operation jeopardises the CE conformity of your lighting system.

Clear recommendations tailored to each application

More light. Lower costs. Better safety.

We plan your LED retrofit – standards-compliant and cost-effective.